Conscious Choice―Shaping Mobility’s Future Through Recycled Materials

At Sony Honda Mobility, we challenge ourselves to envision the future of mobility not only through technology and design, but also through the very materials that shape our vehicles. In addition to the interior materials of the AFEELA 1, recycled aluminum and recycled steel are also integrated into components such as the vehicle frame and hood. This reflects our approach to a future where innovation supports both people and the planet.

Redefining Sustainable Vehicle Development

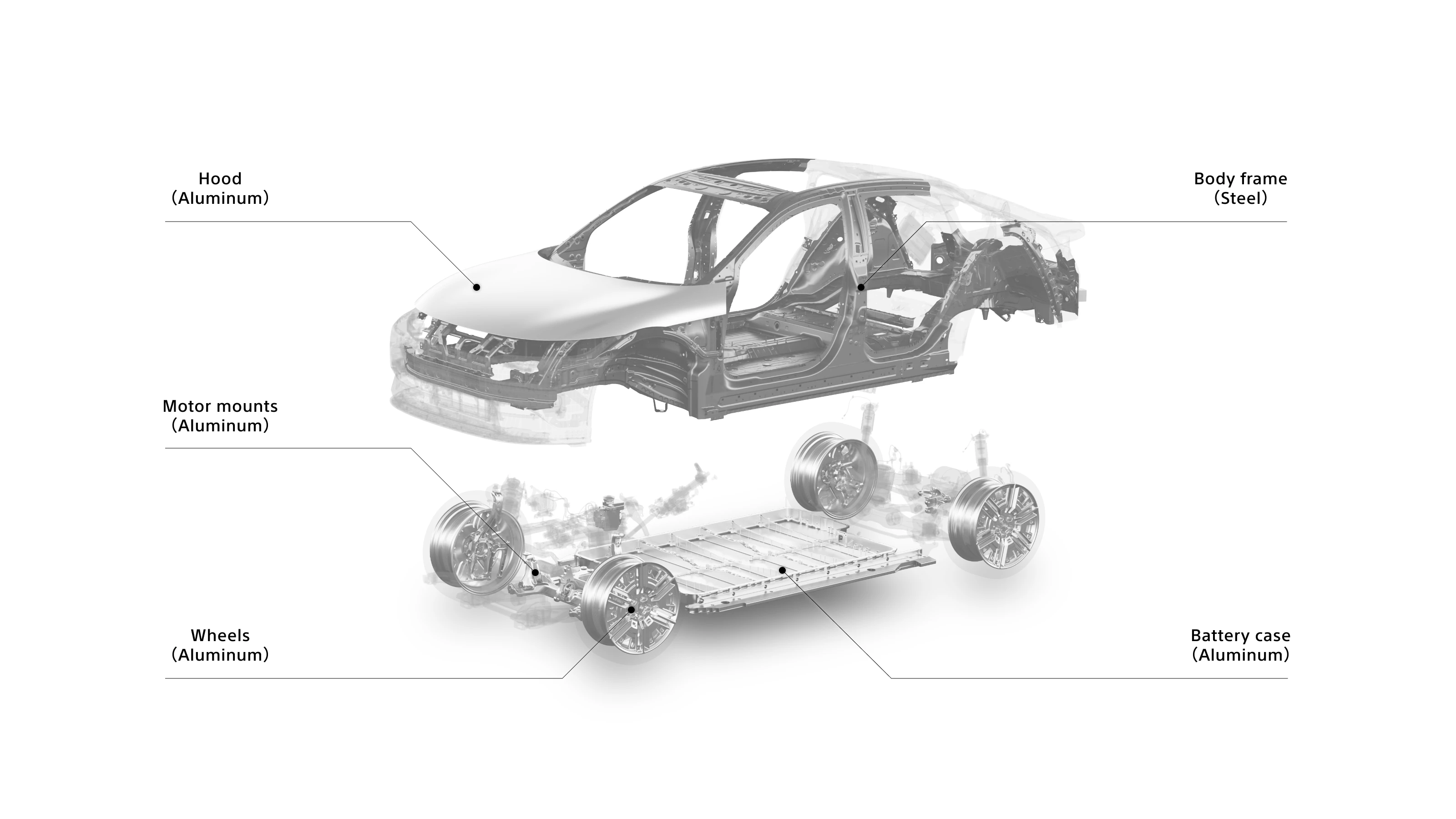

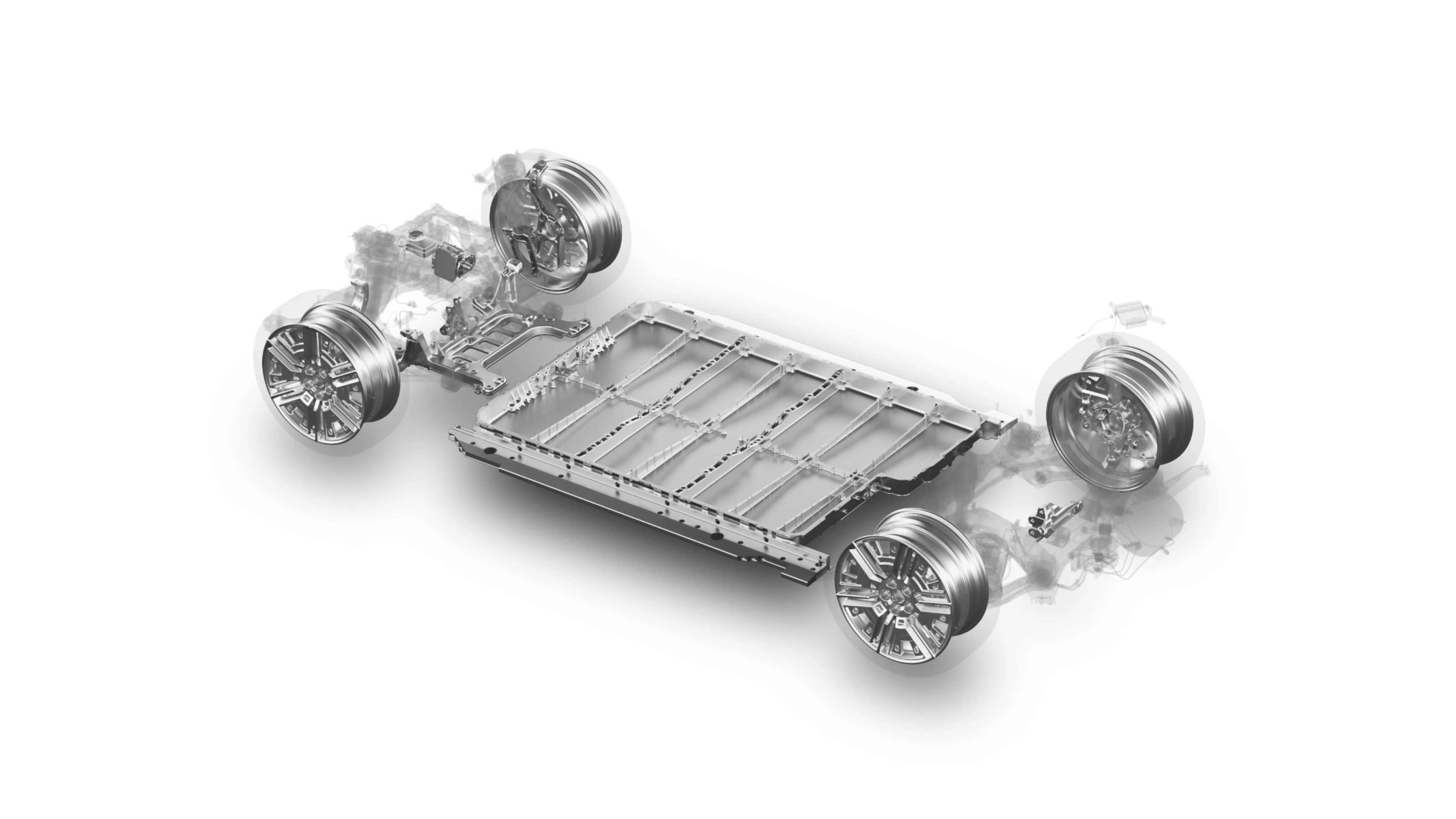

AFEELA incorporates recycled steel and aluminum not only into body steel panels but also into motor mounts* areas where this approach was once difficult to achieve.

*Motor mount refers to a component that secures the motor to the vehicle body and absorbs its vibrations.

Integrating recycled materials into the vehicle frame and other structural components is no simple task. Even slight variations in material performance can influence safety, which is why meticulous design and rigorous validation are essential.

Achieving stable quality depends on trusted partners who support material sourcing, composition analysis, and impurity management. Through repeated testing and simulation, we verify that recycled materials can deliver performance comparable to virgin materials.

Building on these results, at Sony Honda Mobility, we have expanded the use of recycled materials into major load-bearing components, enabling the development of safe and reliable structural parts made with recycled materials. This reflects not only our consideration for the environment, but also demonstrates confidence in our engineering capability.

AFEELA 1 incorporates recycled steel in the body frame, and is designed to accommodate recycled aluminum in key components that underpin safety and driving performance—including the hood, motor mounts, knuckles, and wheels. The battery case is designed to enable the use of fully recycled aluminum in 70% of the weight.

High-Quality Recycled Materials: A Honda Heritage

Our partner Honda’s long-cultivated expertise forms the quiet foundation of this technical challenge—a depth of engineering DNA that now runs through Sony Honda Mobility. Over decades, Honda has refined its mastery of aluminum, making all-aluminum sports-car bodies that balance lightness and rigidity, while drawing on knowledge forged in top-tier motorsport. This understanding spans from complex frame structures to exterior panels, continually pursuing the strength, durability, and precision required of a true performance vehicle.

AFEELA 1 inherits this legacy: the pursuit of high-purity, high-strength recycled aluminum. Through close collaboration with our development partner Honda—as well as trusted suppliers and recycling partners, we are establishing an integrated system that enables the selection and refining of scrap, precise composition control, and robust quality assurance.

In doing so, we aim not only to uphold environmental responsibility, but also to set a standard of craftsmanship that helps shape the future of mobility.

A Choice to Invest in the Future of Materials

Promoting recycling is far more than simply making inexpensive use of scrap. To sustain it responsibly, continued investment in advanced sorting and refining technologies is essential—an approach that does not always align neatly with short-term economic efficiency.

At Sony Honda Mobility, we regard this cost not as a burden, but as an investment in addressing environmental and human-rights issues and in supporting the gradual realization of a circular society. In developing AFEELA, our intention is not only to create advanced technologies and experiences, but also to gently shift how future mobility—and the environment surrounding it—may be perceived.

As the world moves toward circulating limited resources, the selection and design of materials become central questions. This mindset—reimagining the future of mobility by beginning with the materials themselves—is the philosophy that guides Sony Honda Mobility.

*AFEELA vehicles are designed to incorporate recycled steel in the body frame and recycled aluminum in key components that play a critical role in safety and driving performance — including battery case, hood, motor mounts, knuckles, and wheels. For example, the battery case is designed to enable the use of fully recycled aluminum in 70% of the weight. Sony Honda Mobility will continue advancing efforts to further expand the use of recycled materials.

*All content and vehicles shown are for illustrative purposes only and may be subject to change.

*For the latest sustainability information, please also see here.

The specifications and service contents of the products described in the article are as of the published date and are subject to change without notice.

Related